Free Call Now

The process of enhancing property by applying render is nothing new. In fact, this method has been used on buildings for at least seven thousand years both inside and out.

External house rendering is an effective way of stamping our individual styles on our homes and making them look great. You can refresh and enhance your house, adding value and increasing its kerb appeal using a product that's more hardwearing than masonry paint.

Contents

Today's renders are superior in quality to those in the past due to advances in the materials and methods used. One very popular example is monocouche render, a term that comes from the French 'one coat', a reference to the fact that it is applied directly to walls in a single layer*, either sprayed or applied by hand trowel to brick, stone or block work.

(*Although it is one layer it is applied in two coats or passes, which can be confusing!)

It's quicker to apply, helping to keep labour costs down as only one layer is required, so the project will be completed sooner. It also means that scaffolding charges will be lower, as this is charged by the day.

Traditional renders typically require at least two coats, with a base or scratch coat applied first, and the next layer acting as a topcoat. This is a much more time-consuming process than using monocouche render.

One other benefit of monocouche rendering is that it can also be used with external wall insulation systems, a means of improving thermal efficiency in homes with solid walls without a cavity.

Monocouche rendering generally lasts longer than traditional rendering materials and is available in an impressive range of colours and textures. However monocouche render problems do still occur. The product is pre-coloured, so there is no need for the time-consuming task of painting.

They also protect the wall surface from the elements and provide insulation, making the property more energy-efficient.

So, you can see exactly why they are so popular!

As excellent as monocouche render is, it isn't without its problems, just like any other type, such as sand and cement render, lime render, acrylic render or silicone render.

We're about to find out what these issues are, and see what can be done about them.

Monocouche renders first arrived on the scene in the UK during the 1980s and 90s, and they quickly became a popular choice over traditional rendering options.

However, these were early days and the materials and methods were still, in a sense, experimental. Since then, contractors and manufacturers alike have had ample time to explore any issues.

And this is what has been discovered so far:

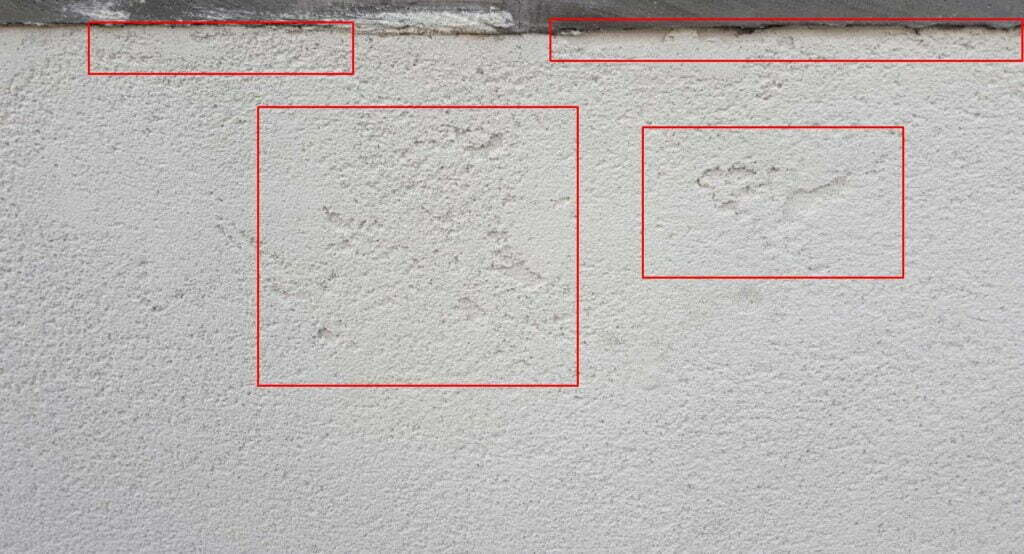

Although it has an expected lifespan of around 25 years, monocouche render can be prone to cracking. This shouldn't come as a surprise, as all renders can crack!

Unless you have a major subsidence issue, these should be limited to hairline cracks. And while they aren't usually too obvious, they can spoil the finish and allow moisture to enter.

The problem is caused by movement in the building structure, which is a fact of life: all buildings shift to some extent. The severity of the cracking problem depends on how much movement there is.

Monocouche render is pretty flexible, so it is more resistant to cracking than sand and cement render. Even so, it is itself a cement render and can still eventually crack over the years if the external wall surface moves.

If a wall is prone to movement, contractors will embed a fibreglass mesh in the first pass that strengthens and supports the render. This should stop hairline cracks from appearing in the future.

Also, to prevent cracking soon after the render is applied, it should not dry too quickly. A professional render expert will know to avoid attempting the job in direct sunlight or high winds and will start work early in the morning if the project is to be completed during the warmer months.

It's important to note that monocouche rendering isn't suitable for painted substrates. Any paint has to be removed before the project goes ahead.

You may have noticed that we get a lot of rain in the UK? This means that you need your render to be as waterproof as possible!

Unfortunately, monocouche render isn't completely hydrophobic. That is, it doesn't usually repel water as silicone render does. However, it is still considered waterproof and weatherproof to a greater extent.

This type of render is microporous, which is excellent for balancing thermal pressure as the wall surface heats up and cools down. The trouble is that this microporosity allows moisture in, which can lead to algae growth that can cause discolouration.

related article: bossed render

This green staining is unsightly and is a pain to clean off if left too long. The best way to avoid it is to apply a siloxane-based sealer over the render. Otherwise, you'll need to be prepared to clean it regularly (see the section on maintenance below) or consider other types of render.

Discuss the options available with your chosen contractor, as these products are being improved continually. They will search for the best brand and product to suit your needs, and they may be able to recommend one that has added components to maximise its waterproof qualities.

Though not impossible, patching up any damage to a monocouche render isn't always easy.

This product comes as a dry powder delivered onsite in bags and mixed with water. It is formulated using white cement with a pigment added, so it is through-coloured. When repairing a damaged section, you need to find an exact colour match, which is very difficult if bold colours have been used in the original render.

The last thing you need is a patch that looks a different colour to the rest of the building as this spoils the whole effect.

This job is made harder the longer the existing render has been in place.

To begin with, use a reputable company. If or when repairs are necessary, these are the people you should contact as they'll have the knowledge and experience to resolve the problem efficiently and quickly.

They will most likely recommend that a thin new coat of render is applied once the repair is complete, as this will achieve a smooth consistent finish across the entire surface.

While not exactly a problem (all renders need some maintenance!), it does mean that you need to do some work to keep it looking fresh and clean.

Opinions and experiences differ, but the general consensus seems to be that monocouche rendering can start to look grubby after a while. Dirt and grime accumulate and algae can sometimes be an issue.

So, you've saved yourself the bother of painting your exterior walls, but you'll need to clean them.

Again, use a reputable rendering professional, as they will apply an antifungal solution to the substrate (the bare wall surface) before they start work.

Ideally, you should also wash your walls down every 6 to 12 months. You can do this by hand or using a pressure washer. However, it's imperative that you set the nozzle to spray rather than jet, or you may destroy the render! It's perhaps best to use a soft brush and soapy water to gently remove dirt. Regular washing is best as it reduces the build-up of grime and algae so you shouldn't need powerful detergents later.

If you live in a region that experiences a lot of bad weather there's an increased risk of dirt or algae accumulating, so you may need to wash render down more frequently. You can use a fungicidal detergent, but always be aware of any hazards to humans, pets and wildlife before use.

One word of caution: monocouche rendering takes around 28 days to harden completely. While it shouldn't need cleaning during this time, it's essential that you don't try to do so or you risk damaging it.

What is clear when researching a subject like this is that many companies and contractors have their own opinions and thoughts about various products. One will endorse silicone render, suggesting that monocouche has had its day, while another will recommend monocouche rendering as the answer to your problems!

However, try to look past this, as there's a strong chance that these are biased reviews based on an agreement between the manufacturer and the contractor to promote a specific product.

If you want unbiased opinions, check out forums where contractors discuss methods and products, as this gives the benefit of their wisdom and experience, often in candid terms!

related article: k rend problems

The fact is that monocouche render still has its place as a practical and cost-effective option. Although problems can arise, they can usually be overcome or avoided, especially when you engage a qualified, competent contractor who knows what they're doing.

They will advise you on the best brand or mix, such as Weber, K Rend or Parex, and will provide a perfect finish in the colour and texture of your choice.

To some extent, the type of property dictates your choice of render: older homes (especially period houses) should ideally use traditional render.

However, monocouche render remains a good-quality, viable and effective solution and will continue to do so for many years to come.